Photoresists & Specialty Chemicals

KMSF® 1000 Low Stress Photo-dielectric

Part of the StructSure™ Line

KMSF® 1000 is a negative tone, polyimide-based photo-dielectric for use as an ultra-low stress buffer, passivation or protective layer.

Material Attributes: |

- Negative tone, photoimageable dielectric

- No warpage due to low shrinkage and tensile modulus

- Solvent developable

- I-Line/broadband sensitivity, 1:1 aspect ratio imaging

- Low temperature processing (< 200°C)

- Good electrical properties

- High thermal and chemical stability

- Low moisture uptake

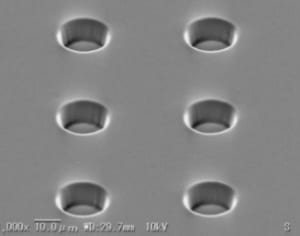

20 µm via

10 µm Film Thickness

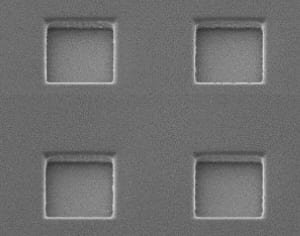

50 µm via

10 µm Film Thickness

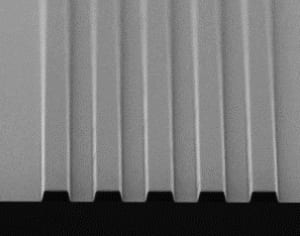

15 µm L/S

10 µm Film Thickness

Lithography Process

| Type | Liquid Negative Tone |

| Film Thickness |

~ 3 to 10 µm |

| Soft Bake | 110°C, 10 minutes |

| Exposure Dose | > 400 mJ/cm2 (EVG Broadband aligner) Proximity, intensity measured at 365 nm) |

| Development | Spray develop with KMSF® Developer 23˚C, 70 rpm, 60 seconds spray, 60 seconds puddle + 60 seconds spray |

| Rinse | Spray rinse in KMSF® Developer 23˚C, 70 rpm, 10 seconds + 2000 rpm, 15 seconds |

| Hard Bake | 175°C, 60 minutes |

Cured Film Properties

| Property | Value | |

| Mechanical Properties | Young’s Modulus | 0.14 GPa |

| Tensile Strength | 37 MPa | |

| CTE α1 (<Tg) | 140 ppm/˚C | |

| Elongation | 160% | |

| Residual Stress | 0.2 MPa | |

| Thermal Properties | Tg (TMA) | 57˚C |

| 5% Weight Loss Temperature in N2 | 420°C | |

| Electrical Properties | Volume Resistivity | 1.8 x 1015 Ohm·cm |

| Electric Strength | 1.8 kV/10 µm | |

| Dielectric Constant, 1GHz | 2.6 | |

| Dissipation Factor , 1GHz | 0.008 | |

| Water Absorption | Moisture Absorption (23˚C/85%RH, 24 hours) | 0.1% |

LEARN MORE>

Wafer Warpage Comparison

Wafer size/thickness: 200 mm/50 µm

Material film thickness: 10 µm

FEATURED APPLICATIONS