Photoresists & Specialty Chemicals

KMSF® 2000 Low Dk/Df Photo-dielectric

Part of the StructSure™ Line

KMSF® 2000 is a negative-tone, low-temperature cure, PPE-copolymer-based photo-dielectric for high reliability heterogeneous design in advanced packaging. It provides a unique advantage offering through its improved pattern resolution, low temperature cure, and robust balance of mechanical and electrical properties. It is designed for an optimal cured film thickness of 5 to 10 μm.

Material Attributes: |

- Negative tone, photoimageable dielectric

- 5 to 10 µm film thickness after cure

- Solvent-developable in PGMEA

- I-Line/broadband sensitivity, 1:1 aspect ratio imaging

- Low temperature cure ≤ 200°C

- Low Dk/Df electrical properties

- Low moisture uptake

- Good thermal and chemical stability

Material Uses: |

- RDL dielectric

- Passivation and protective layer

- Wafer level packaging

Lithography Process

| Process Steps | Conditions for 5 μm Thick Process with KMSF® 2005 |

Conditions for 10 μm Thick Process with KMSF® 2010 |

| Substrate | 150 and 200 mm Cu wafer | |

| Spin-speed | 2500 rpm/ 30 seconds | 1900 rpm/ 30 seconds |

| Soft Bake | 95°C, 3 minutes (hot plate) | 95°C, 4 minutes (hot plate) |

| Exposure | 250 mJ/cm2 ABM broadband mask aligner with intensity measured at 365 nm |

|

| PEB | 110°C, 2 minutes (hot plate) | |

| Development | PGMEA-based Developer 6 x 60 seconds puddle | |

| Hard Bake | 200°C under nitrogen, 60 minutes | |

Cured Film Properties

| Property | Value | |

| Process | Available Viscosities | ~800 cSt ~1600 cSt |

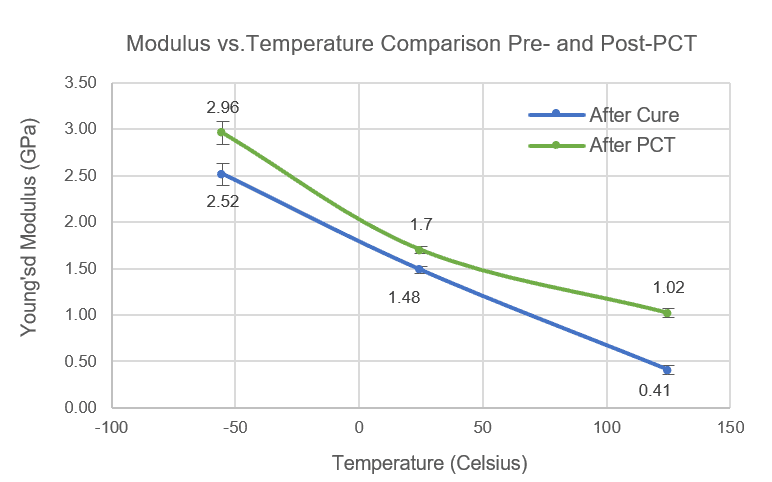

| Mechanical Properties | Young’s Modulus | 1.6 GPa |

| Tensile Strength | 60 MPa | |

| CTE α1 (<Tg) | 60 ppm/˚C | |

| Elongation | 65% | |

| Residual Stress | 14 MPa | |

| Thermal Properties | Tg (DMA) | 215˚C |

| 5% weight loss temp. in N2 | 390˚C | |

| Electrical Properties | Volume Resistivity | 6.7 x 1016 Ohm·cm |

| Breakdown Voltage | 270 V/µm | |

| Dielectric Constant, (10-50 GHz) |

2.5 | |

| Dissipation Factor, (10-50 GHz) |

0.003 | |

| Water Absorption | Moisture Absorption (23˚C/85% RH, 24 hours) |

0.03% |

Reliability

HAST (PCT): 121ºC/100% RH, 2 atm, 48 hours

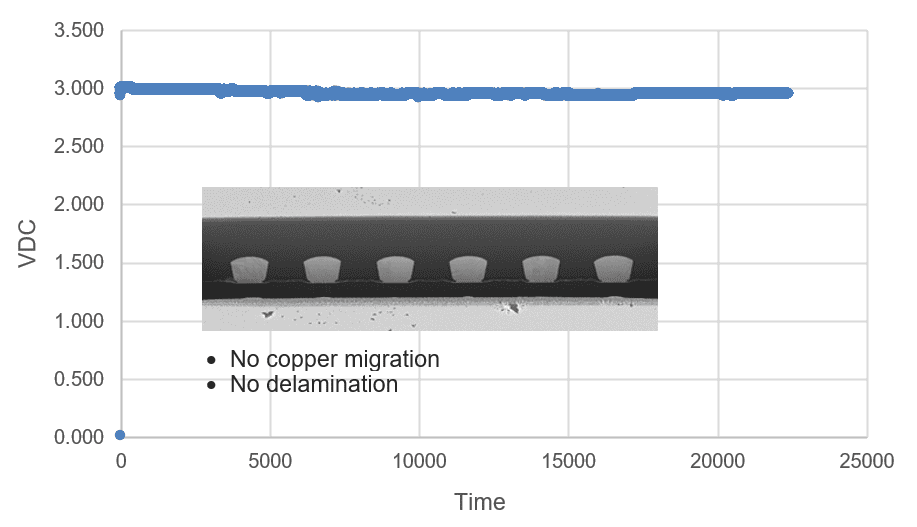

BIAS HAST: 85°C/85% RH, 3.3 volts, 168 hours

(5 µm L/S Cu structure)

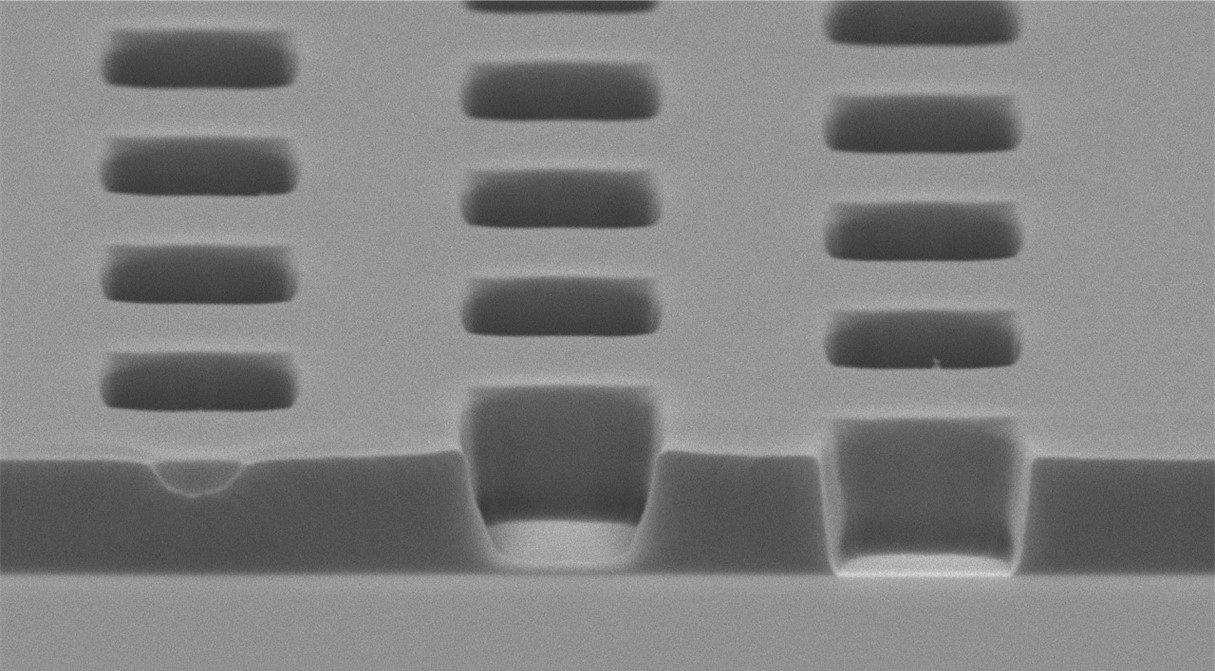

10 µm via

10 µm Film Thickness

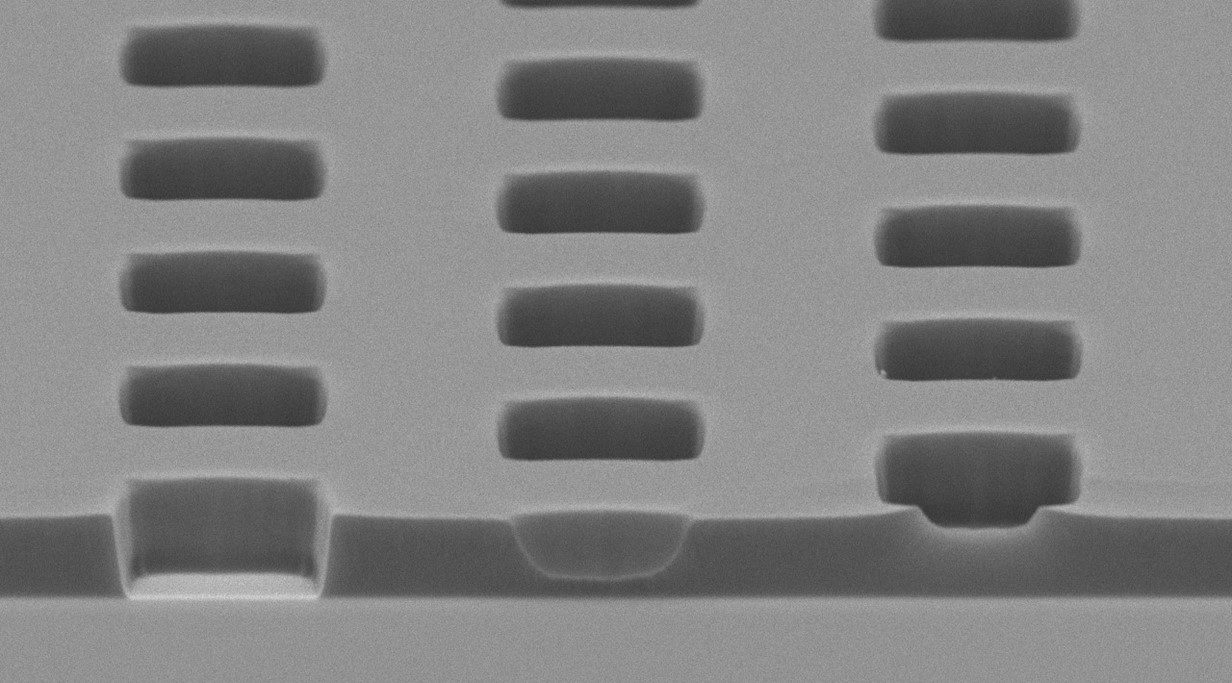

15 µm via

10 µm Film Thickness

FEATURED APPLICATIONS