Photoresists & Specialty Chemicals

TempKoat™ P Positive Temporary Photoresist

Part of the Kayaku Advanced Materials Line

TempKoat™ P is a chemically amplified, positive-tone resist series for advanced packaging and MEMS applications.

TempKoat™ P 20 is the first dilution available in the TempKoat™ P series.

Material Attributes:

|

Material Uses:

|

Lithography Process for TempKoat™ P 20

| Substrate | 150 mm Cu wafer |

| Spin Speed | 2000 rpm/30 seconds |

| Film Thickness | 20 µm |

| Soft Bake | 120°C, 3 minutes (hot plate) |

| EBR | ~ 1.5 mm removal with EBR PG

500 rpm, 30 second + 65˚C for 1 minute (hot plate) |

| Exposure | 350 mJ/cm2

ABM Broadband aligner with 360 nm long pass filter Intensity measured at 365 nm |

| PEB | 95°C, 2 minutes |

| Development | Spray develop with 0.26N TMAH Developer 4 x 60 seconds puddle |

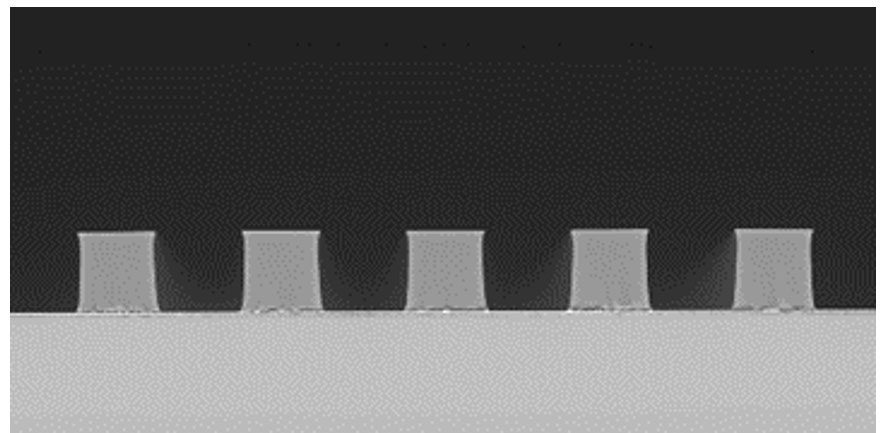

20 µm L/S in 20 µm thick resist

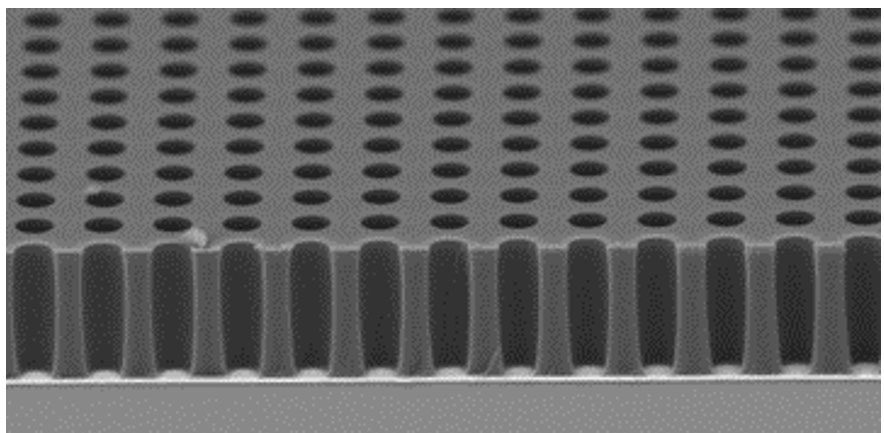

5 µm vias in 20 µm thick resist

Cu Plating Process for TempKoat™ P 20

| Surface Prep. | O2 Plasma

80SCCM, 350W, 3 minutes |

| Technic Elevate® Cu 6300 Cleaner (or equivalent)

room temperature, 1.5 minutes, shaker table |

|

| Plating | Technic Elevate® Cu 6388

I = 0.83A, 16.67 minutes, 80˚F |

| Resist Removal | NMP-based remover (Remover PG)

Immersion and agitation for 15 minutes at ambient |

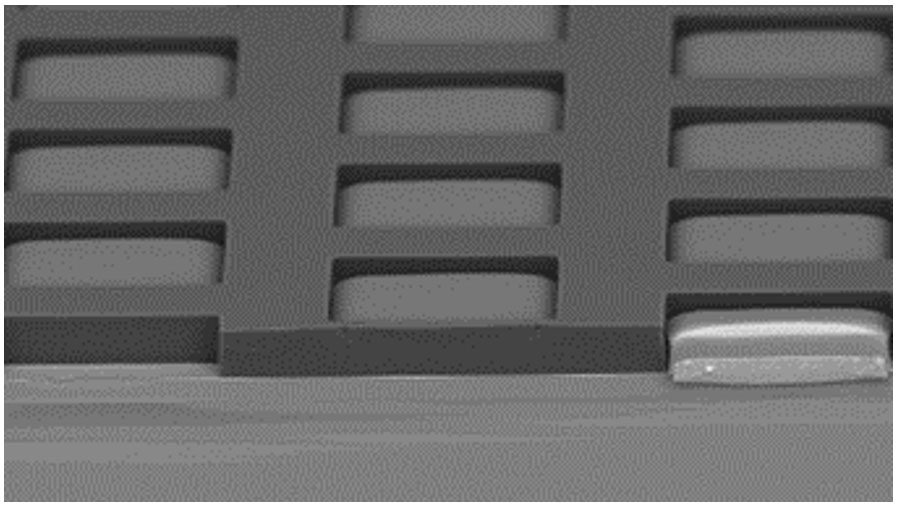

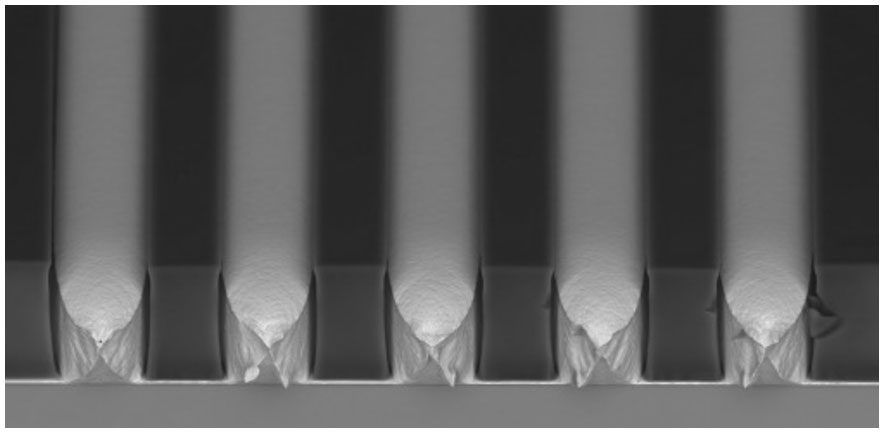

100 µm Cu posts plated to 20 µm

before resist removal

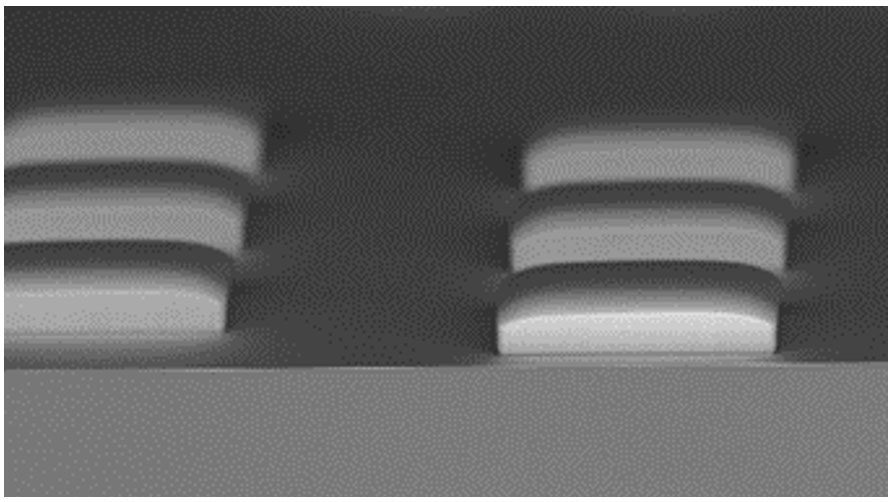

100 µm Cu posts plated to 20 µm

after resist removal

LEARN MORE>

20 µm plated Cu L/S in 32 µm thick resist

FEATURED APPLICATIONS