KMPR® 1000

Part of the StructSure® Line

Material Uses:

Electroplating

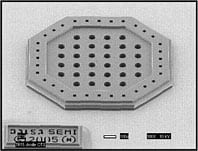

DRIE

Permanent Structures

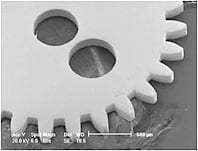

Electroformed Ni gear after stripping KMPR®

Source: Univ. of Birmingham

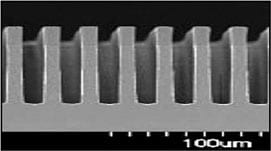

Plating (100 μm tall Ni posts, KMPR® removed)

Key Features

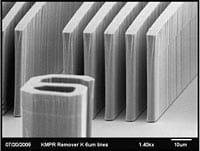

- High aspect ratio imaging

Vertical sidewalls - Greater than 100 μm film thickness in a single coat

- Aqueous developer compatible (TMAH & KOH)

- Wet stripping in conventional strippers

- Excellent dry etch resistance

Application Notes

Process Parameters

Coat

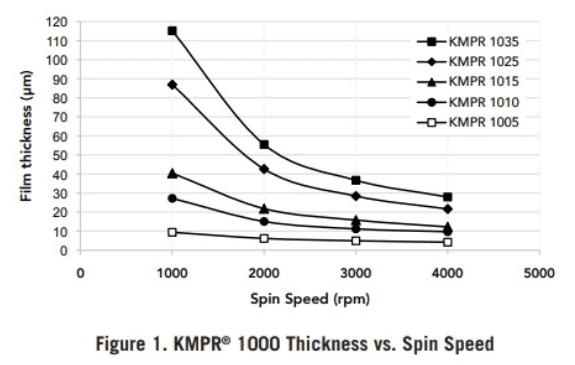

KMPR® 1000 resists are available in five standard viscosities, as shown in Table 1. Figure 1 provides the information required to select the appropriate KMPR® 1000 resist and spin conditions, to achieve the desired film thickness.

Recommended Program

1. Dispense 1 ml of resist for each inch (25 mm) of substrate diameter

2. Spin at 500 rpm for 5–10 seconds with acceleration of 100 rpm/second

3. Spin at 3000 rpm for 30 seconds with acceleration of 300 rpm/second

Soft Bake

Table 2 shows the recommended soft bake temperature and times for the various KMPR® 1000 products at selected film thicknesses. The recommended bake temperature is 100ºC, however temperatures from 95–105ºC may also be used.

Exposure

To obtain vertical sidewalls in the KMPR® 1000 resist, we recommend the use of a longpass filter to eliminate UV radiation below 350 nm. With the recommended filter (PL-360LP), an increase in exposure time of approximately 40% is required to reach the optimum exposure dose.

Post Exposure Bake

A post exposure bake (PEB) is required to complete the curing reaction and should take place directly after exposure. Table 5 shows the recommended times and temperature for various approximate thickness targets. The recommended temperature is 100˚C, however temperatures from 95–105˚C may also be used.

Development

KMPR® 1000 resist has been designed for use with 2.38% TMAH (0.26N) aqueous alkaline developer in immersion, spray or spray-puddle processes. Other solvent based developers such as SU-8 developer may also be used instead of TMAH. Strong agitation during development is recommended for high aspect ratio and/or thick film structures. Recommended develop times for immersion processes are given in Table 6 for TMAH and Table 7 for SU-8 developer. These develop times are approximate, since actual dissolution rates can vary widely as a function of agitation.