Photoresists & Specialty Chemicals

C-MEMS & C-NEMS: 3D Carbon Microfabrication

Part of the Applications Notes Line

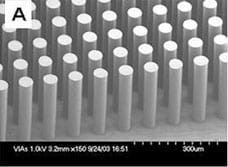

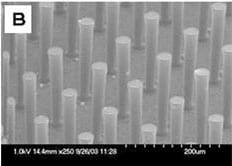

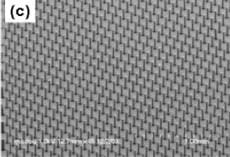

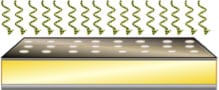

C-MEMS—in which patterned photoresist is pyrolyzed in an inert environment at high temperature—constitutes a powerful approach to building 3D carbon microelectrode arrays for 3D micro battery applications. High aspect ratio carbon posts are achieved by pyrolyzing SU-8 negative photoresist in a simple one step process.

C-MEMS technology is useful for 3D microarray due to C having attractive properties. These include mechanical durability, electrical conductivity, and chemical stability. High aspect ratio with low cost is obtained by using SU-8 with conventional photolithography followed by pyrolysis.

SU-8: Benefits/Attributes

- High aspect ratio

- Near vertical sidewalls

- >200 µm in a single spin coat

- No popping or voids created in resist structures after exposure

- Conductivity after pyrolysis of 1000°C for 1 hour, the SU-8 is similar to glassy carbon

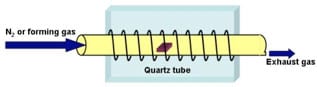

Pyrolysis Chamber

Pyrolysis of SU-8

SU-8 posts

Pyrolized SU-8 posts

3D C-MEMS posts

3D C-MEMS posts

1. Coat and bake SU-8 2100

2. The SU-8 layer is exposed.

3. The SU-8 layer is post exposure baked.

4. Development

5. Pyrolysis

6. Carbon structures

SEM images and C-MEMS process courtesy of Chunlei Want@FIU and Marc Madou@UCI