TempKoat® P Positive Temporary Photoresist

Part of the StructSure® Line

TempKoat® P is a chemically amplified, positive-tone resist series for advanced packaging and MEMS applications.

TempKoat® P 20 is the first dilution available in the TempKoat® P series.

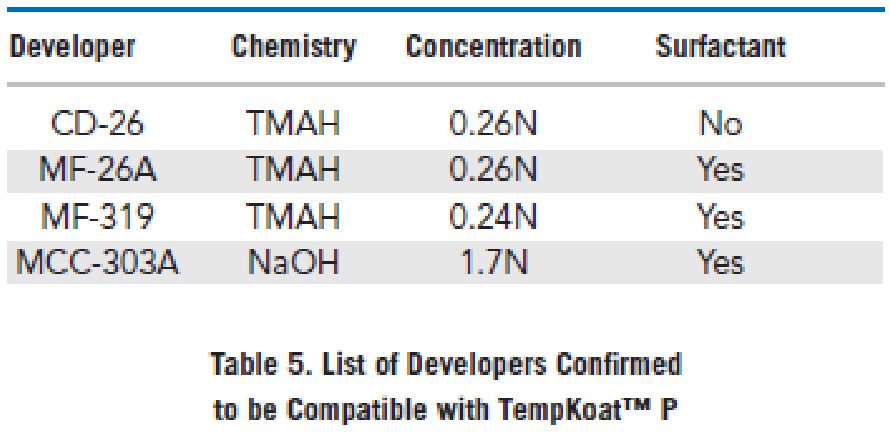

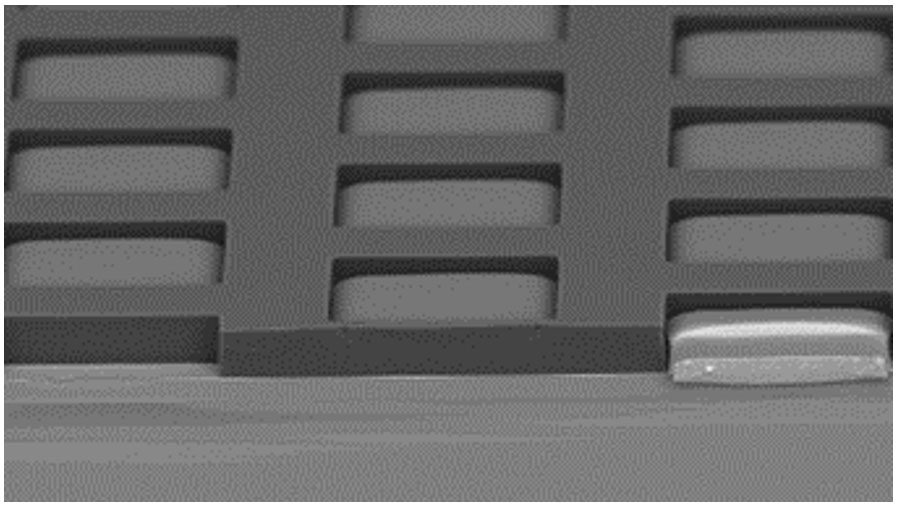

20 μm plated Cu L/S in 32 μm thick resist

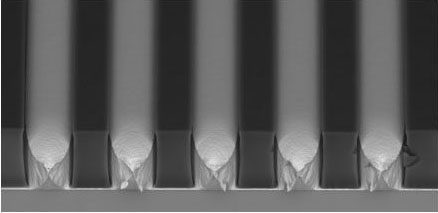

20 μm L/S in 20 μm thick resist

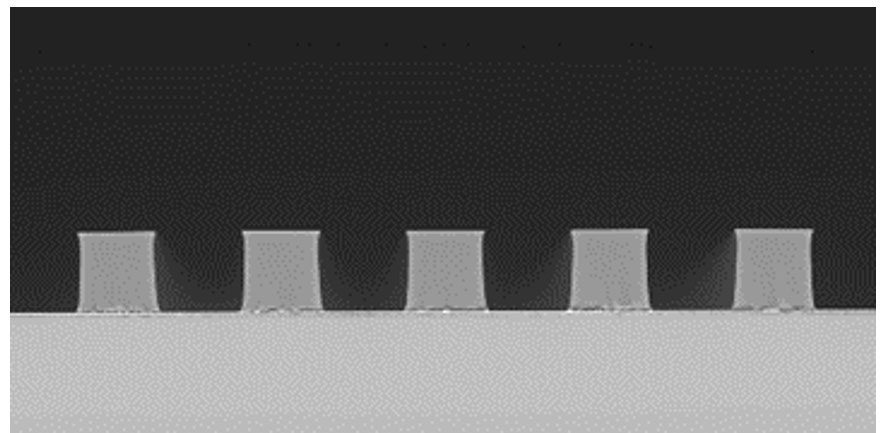

5 µm vias in 20 µm thick resist

Key Features

- Positive tone, chemically amplified resist

- 10 to 40 μm film thickness in a single coat

- i-Line/broadband sensitivity, 3:1 achievable aspect ratio

- No rehydration or latency delay

- Aqueous alkaline development (standard 0.26N TMAH)

- Excellent chemical resistance and residue-free removal

Material Uses

- Electroplating

- RDL

- Microbumping

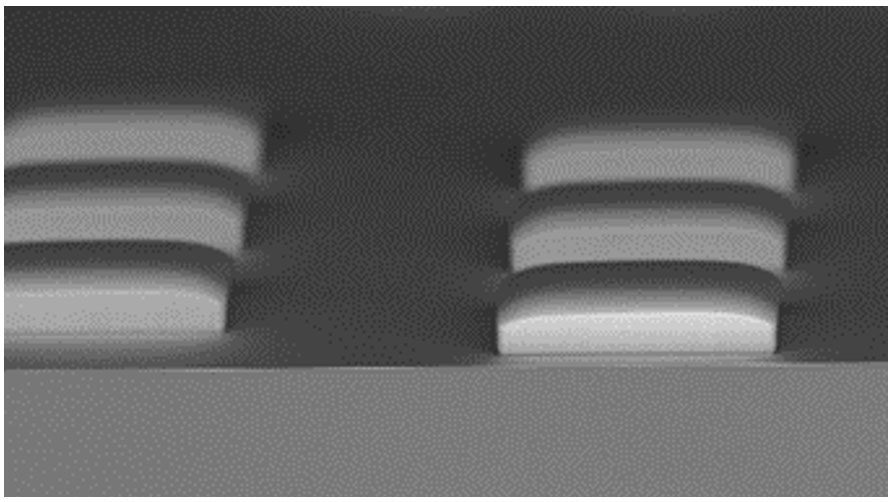

100 µm Cu posts plated to 20 µm before resist removal.

100 µm Cu posts plated to 20 µm after resist removal

Cu Plating Process for TempKoat® P 20

| Surface Prep. | O2 Plasma

80SCCM, 350W, 3 minutes |

| Technic Elevate® Cu 6300 Cleaner (or equivalent)

room temperature, 1.5 minutes, shaker table |

|

| Plating | Technic Elevate® Cu 6388

I = 0.83A, 16.67 minutes, 80˚F |

| Resist Removal | NMP-based remover (Remover PG)

Immersion and agitation for 15 minutes at ambient |

Process Parameters

Coat

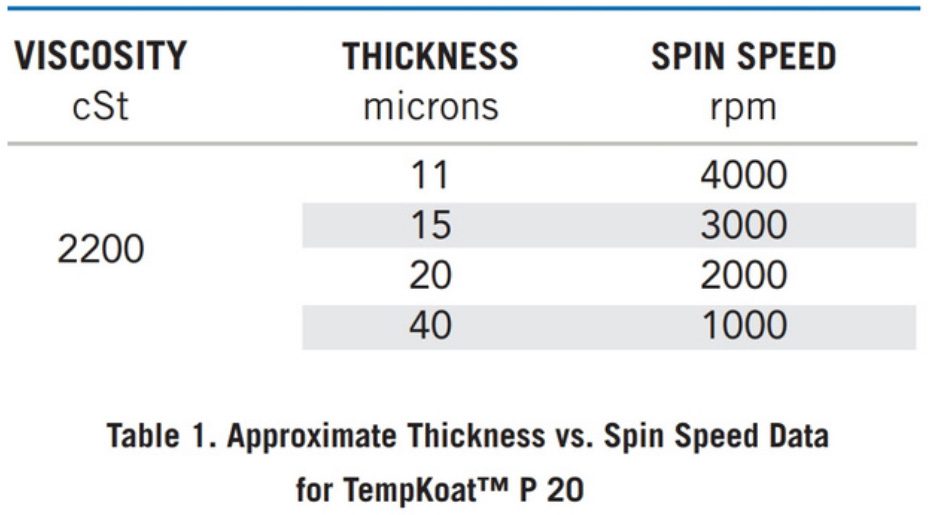

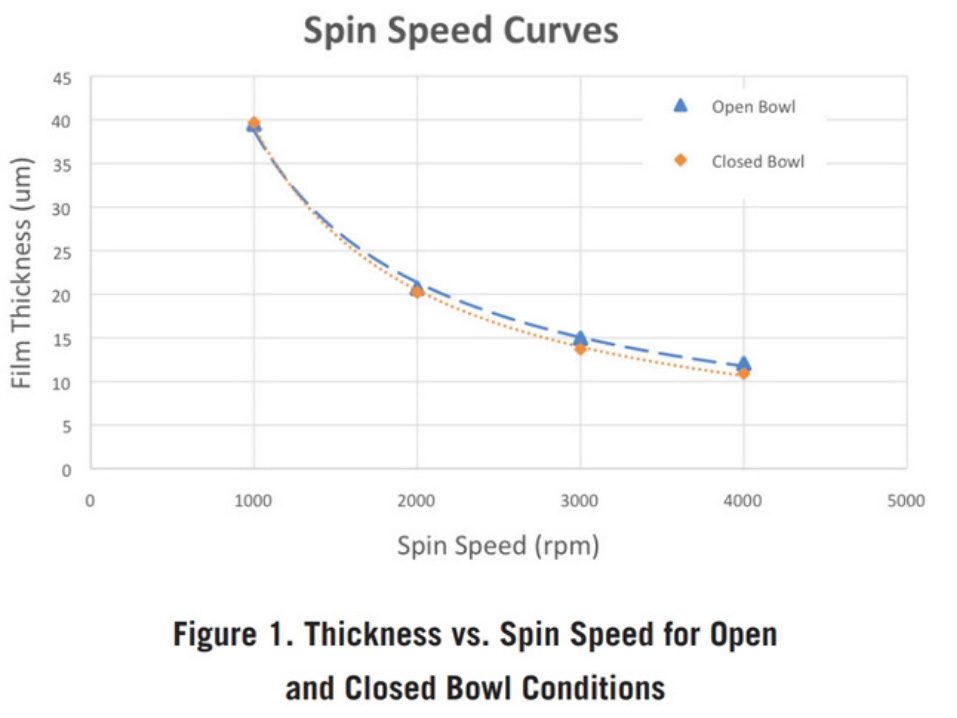

TempKoat® P 20 is optimized for coating thicknesses from 10 to 25 μm. The resist is capable of coatings with minimal thickness variation. The film thickness versus spin speed data displayed in Table 1 and Figure 1 provide the information to select the appropriate TempKoat® P 20 spin conditions. This will allow the user to achieve the desired film thickness

Recommended Coating Conditions

- Static/Dynamic Dispense: Approximately 1ml of TempKoat® P per inch of substrate diameter.

- Spread Cycle: Ramp to 1000 rpm at 1000 rpm/ second acceleration. Immediately move to spin cycle step, no hold time necessary.

- Spin Cycle: Ramp to final spin speed at an acceleration of 1000 rpm/second and hold for a total of 30 seconds.

Soft Bake & Edge Bead Removal

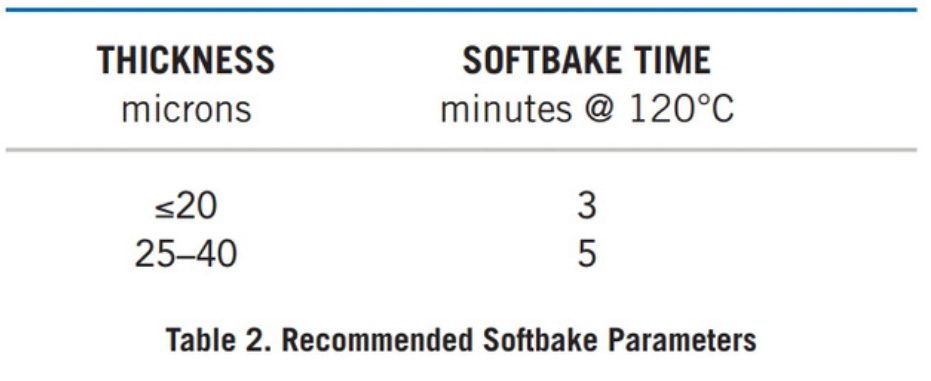

An edge bead removal step can be done immediately following spin coating using Kayaku Advanced Materials’ EBR PG. Following the edge bead removal, the remaining solvent must be evaporated by softbaking. This will densify the film. TempKoat® P should be baked on a level, contact hotplate. For thicknesses up to 20 μm, it is not necessary to ramp or step-up softbake temperature.

Exposure

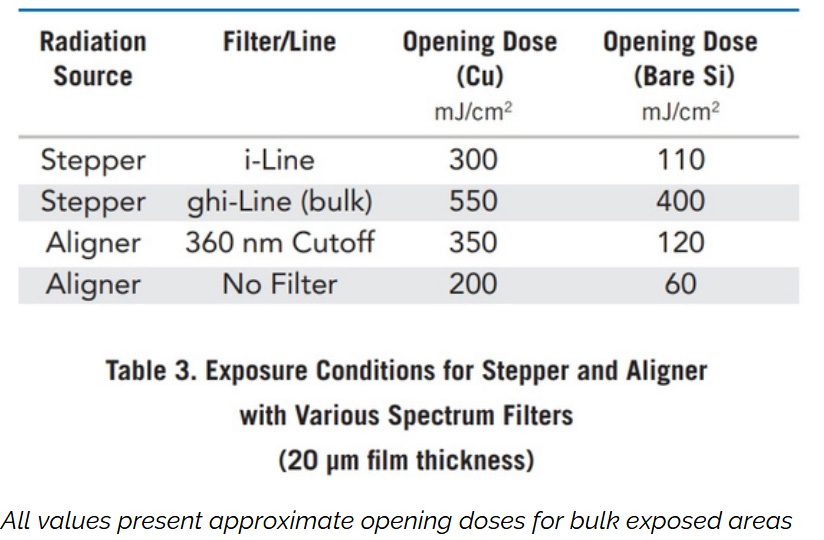

TempKoat® P 20 is optimized for near UV (350-450 nm) exposure. The resist responds optimally to i-Line exposure. The resist is much less sensitive to h and g-Line radiation; however, exposure conditions for a 20 μm thick resist coating are listed in Table 3. The processing window identifying the exposure latitude can be found in the subsequent section for both Silicon and Copper substrates. Exposure dose recommendations are based on source intensity measurements taken with an i-Line (365 nm) radiometer and probe for both the Hg lamp contact aligner and stepper. The stepper ghi-Line is calibrated with a 400 nm OAI probe.

Note: Optimal exposure will produce a visible latent image after being placed on the PEB hotplate and not before. A visible latent image before the PEB step indicates excessive exposure. An exposure matrix experiment should be performed to optimize the exposure dose.

Exposure Tip: When using a broad spectral output source, for best imaging results, i.e. straightest sidewalls, filter out higher energy wavelengths below 360 nm.

Development

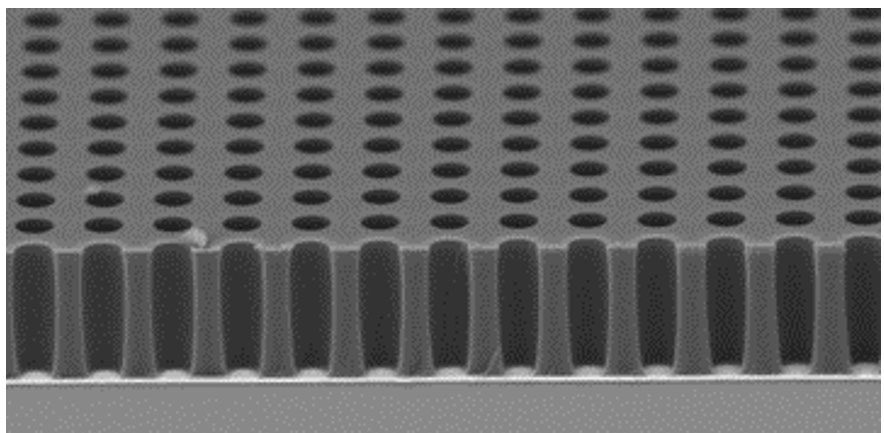

TempKoat® P resist has been designed for use with 2.38% TMAH (0.26N) aqueous alkaline developer. Many alkaline based developers are compatible with TempKoat® P, including surfactant and surfactant-free variations of both metal-ion-bearing and metal-ion-free developers, see Table 5. Process optimization is necessary for different developer chemistries to achieve desired performance.

Spray development is recommended with four separate 1-minute puddle steps. Immersion and continuous spray processes for development can be implemented but require user optimization. Increased development time or agitation are not recommended to improve residue removal. Additional sure or increased PEB temperature or time are the best processing variables to improve feature shape and residue removal.