SU-8 XFT 75 & 100

Part of the StructSure® Line

The SU-8 XFT series is a high contrast, epoxy-based photoresist designed for micromachining and other microelectronic applications, where an ultra-thick, chemically and thermally stable image is desired. SU-8 XFT has been formulated for ultra thick film processes with improved adhesion and lower coating stresses. Film thicknesses of 50 to >200 microns can be achieved with a single coat process. The SU-8 XFT series has excellent imaging characteristics and is capable of producing very high, over 5:1 aspect ratio structures, with near vertical sidewalls.

Contact aligner exposure

Left to right: 25 μm, 20 μm, 15 μm and 14 μm L/S

in 100 μm SU-8 XFT100 coating

KAM Recommended Replacements for SU-8 2000

SU-8 TF 6000

For your high resolution ≤ 10 µm thin film needs process

SU-8 TF 3000

For your 10 to 50 µm film thickness process needs

For your ultra thick film process needs 50-200 µm

Contact aligner exposure

14 μm features, 100 μm SU-8

XFT100 coating

Material Uses

- Fabrication of PDMS molds

- Stamps

- Dry etch masks

- Waveguides

- Microfluidics

- Rapid prototyping

- Structural components such as micro arrays, fluidic channels, display pixel walls and dielectric layers

Key Features

- High aspect ratio imaging of ultra-thick structures

- Vertical sidewalls

- i-line (365 nm) and broadband processing

- Improved adhesion

- Reduced coating stress

- 50 to 200 μm film thickness in a single coat

Process Parameters

Coat

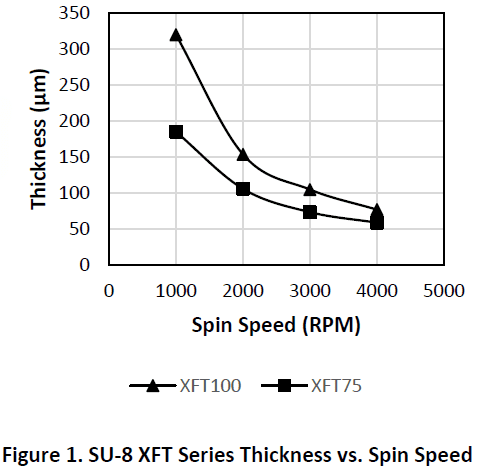

SU-8 XFT resists are available in two standard viscosities, 22,000 cSt for SU-8 XFT75 and 45,000 cSt for SU-8 XFT100. The film thickness vs. spin speed curve is displayed in Figure 1. The curve was generated on a 6-inch (150 mm) silicon wafer using a closed bowl configuration.

Recommended Coating Conditions

- Dispense 1 ml of resist for each inch (25mm) of substrate diameter.

- Spin at 500 rpm for 5–10 seconds with acceleration of 100 rpm/second.

- Spin at 3000 rpm for 30 seconds with acceleration of 1000 rpm/second.

Soft Bake

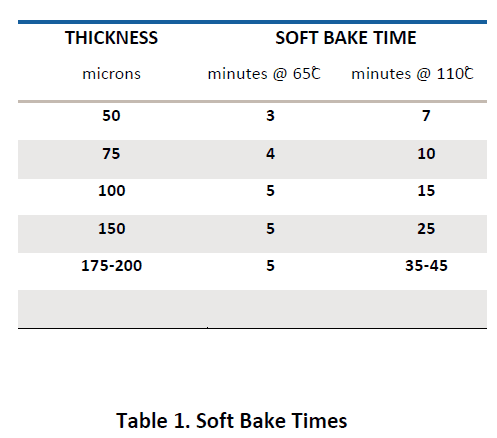

A level hotplate with good thermal control and uniformity is recommended for use during the soft baking step of the process. Table 1 shows the recommended soft bake temperatures and times for various film thicknesses of SU-8 XFT.

Exposure

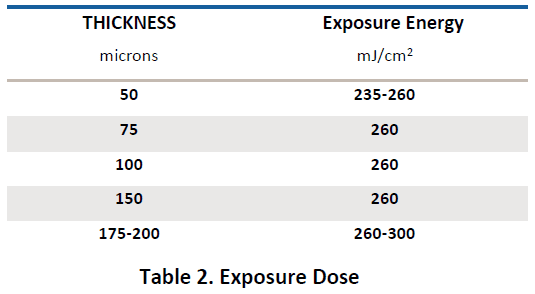

To obtain vertical sidewalls in the SU-8 XFT resist, we recommend the use of a long pass filter to eliminate UV radiation below 350 nm. A typical exposure dose with measured intensity at 365 nm for 50 to 200 μm films are listed in Table 2.

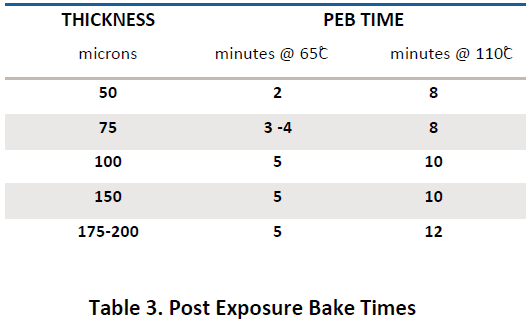

PEB should take place directly after exposure. Table 3 shows the recommended temperatures and times.

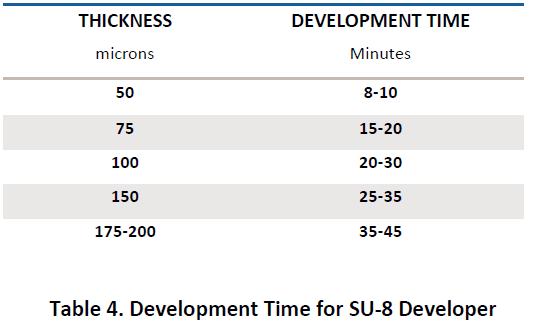

Development

SU-8 XFT photoresist has been designed for use in immersion or spray-puddle processes with Kayaku Advanced Materials’ SU-8 developer.

The recommended baseline development times using an immersion process with mild agitation (40 rpm) through an orbital shaker is given in Table 4.

If using a spray/puddle process, 3-minute SU-8 Developer puddles are recommended.