Photoresists & Specialty Chemicals

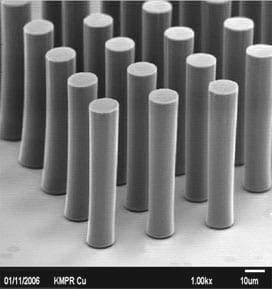

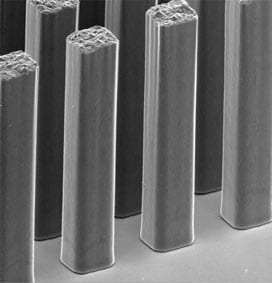

High Aspect Ratio (HAR) Micro-plated Structure Using KMPR®

Part of the Applications Notes Line

KMPR®: Benefits/Attributes

- High aspect ratio imaging with vertical sidewalls

- Up to 100+ µm in a single spin coat

- Compatible with standard aqueous developers

- No cracking

- Strippable with standard wet or dry chemistry

- Excellent metal adhesion

- Excellent plating bath stability

Process Flow

![]()

1. KMPR® is coated onto seed layer.

![]()

2. KMPR® is exposed.

![]()

3. KMPR® is post-exposure baked.

![]()

4. KMPR® is developed.

5. KMPR® is electroplated.

Removal of KMPR®

6. Immersed in NMP (MCC’s Remover PG), KMPR® swells.

7. Further immersed in heated NMP, KMPR® continues to swell and then to lift.

8. Depending on resist thickness, plasma (O2/CF4) may be required. KMPR® is removed. Rinse.

9. Result: High aspect ratio (HAR) plated structures.

50 μm tall Cu post grid array, KMPR® removed

Source: Kayaku Advanced Materials, Inc.

Resist thickness: 800 nm Lines and spaces: 250 nm