Photoresists & Specialty Chemicals

Lithography Overviews

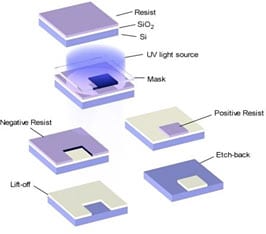

Positive vs. Negative Tone Photoresists

Subtractive vs. Additive Process >

Positive tone resists

The resist is exposed with UV light where the underlying material is to be removed. In these resists, exposure to the UV light changes the chemical structure of the resist so that it becomes more soluble in the developer. The exposed resist is then washed away by the developer solution, leaving windows of the bare underlying material. The mask, therefore, contains an exact copy of the pattern which is to remain on the wafer, as a stencil for subsequent processing.

Examples of positive resist include:

| MCC | PMMA Series (e-beam) |

| DuPont | S1800 Series (g-Line) |

| DuPont | SPR-220 (i-Line) |

| MRT | ma-P1200 Series (broadband) |

Negative tone resists

Negative tone resists behave in the opposite manner.

When exposed to the UV light, the negative resist becomes crosslinked/polymerized, and more difficult to dissolve in developer. Therefore, the negative resist remains on the surface of the substrate where it is exposed, and the developer solution removes only the unexposed areas. Masks used for negative photoresists, therefore, contain the inverse or photographic “negative” of the pattern to be transferred. The figure above shows the pattern differences generated from the use of a positive and negative resist.

Examples of negative resist include:

| MCC | SU-8 Series (i-Line) |

| MCC | KMPR® Series (i-Line) |

| DuPont | UVN-30 (DUV) |

| MRT | ma-N 1400 Series (i-Line) |

| MRT | ma-N 2400 Series (DUV) |

LEARN MORE>

To learn more on this subject, we recommend the following additional reading:

Polymer Materials for Microlithography, Elsa Reichmanis, Larry F. Thompson, Chem. Rev., 1989, 89 (6), pp 1273-1289. Publication Date: September 1989

Handbook of Microlithography, Micromachining, and Microfabrication, Volume 1, P. Rai-Choudhury, SPIE Series

Handbook of VLSI Microlithography: Principles, Technology and Applications, William B. Glendinning, John N. Helbert, 1991

Principles of Lithography, Third Edition (SPIE Press Book), Harry J. Levinson, 2011

Comparison: positive vs. negative tone photoresists