SU-8 3000

Part of the StructSure® Line

Source: Kayaku Advanced Materials, Inc

Key Features

- Improved adhesion

- Reduced coating stress

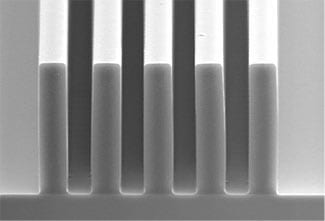

- Vertical sidewalls

- Greater than 100 μm film thickness in a single coat

- Excellent dry etch resistance

Material Uses

- Microfluidics

- Stamps

- Waveguides

Application Notes

Process Parameters

Coat

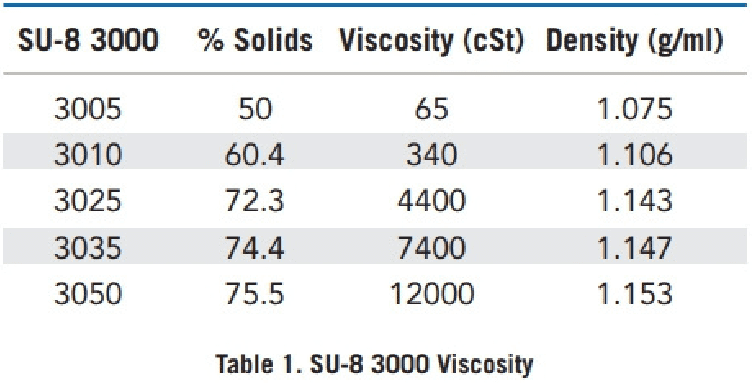

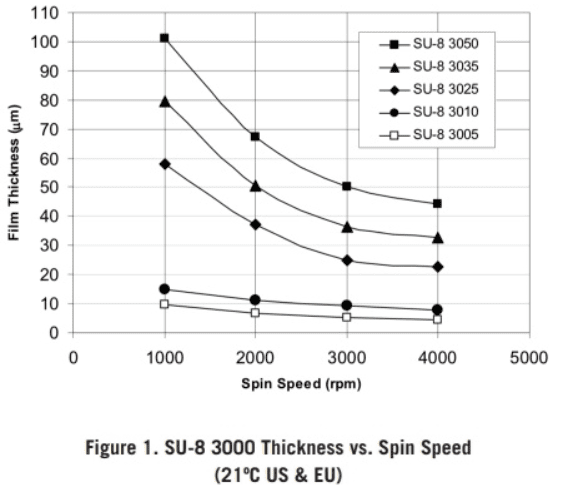

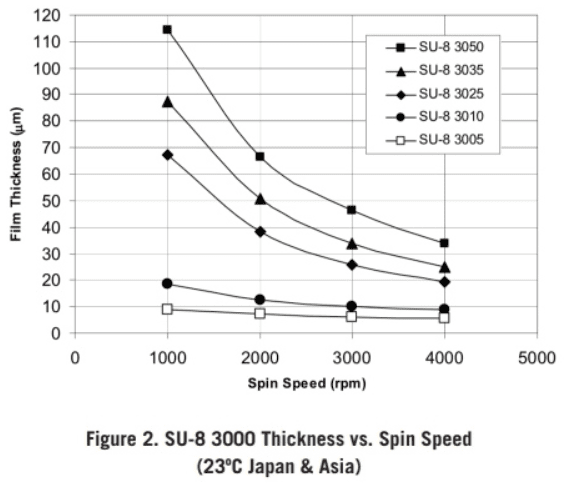

SU-8 3000 resists are available in five standard viscosities, shown in Table 1. Figure 1 provides the information required to select the appropriate SU-8 3000 resist and spin conditions to achieve the desired film thickness.

Recommended Coating Conditions

- Dispense 1 ml of resist for each inch (25 mm) of substrate diameter

- Spin at 500 rpm for 5-10 sec with acceleration of 100 rpm/second

- Spin at 3000 rpm for 30 sec with acceleration of 300 rpm/second

Soft Bake

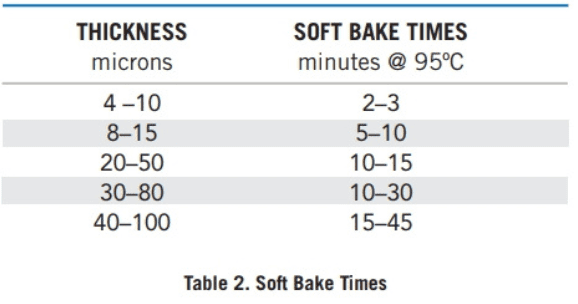

A level hotplate with good thermal control and uniformity is recommended for use during the soft bake step of the process. Convection ovens are not recommended. During convection oven baking, a skin may form on the resist. This skin can inhibit the evolution of solvent, resulting in incomplete drying of the film and/or extended bake times. Table 2 shows the recommended soft bake temperatures and times for the various SU-8 3000 products at selected film thicknesses.

Note:

To optimize the baking times/conditions, remove the wafer from the hotplate after the prescribed time and

allow to cool to room temperature. Then, return the wafer to the hotplate. If the film wrinkles, leave the

wafer on the hotplate for a few more minutes. Repeat the cool-down and heat-up cycle until wrinkles are no

longer seen in the film after placing the wafer on the hotplate.

Exposure

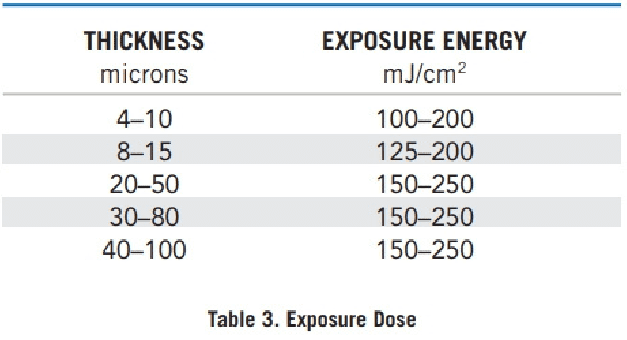

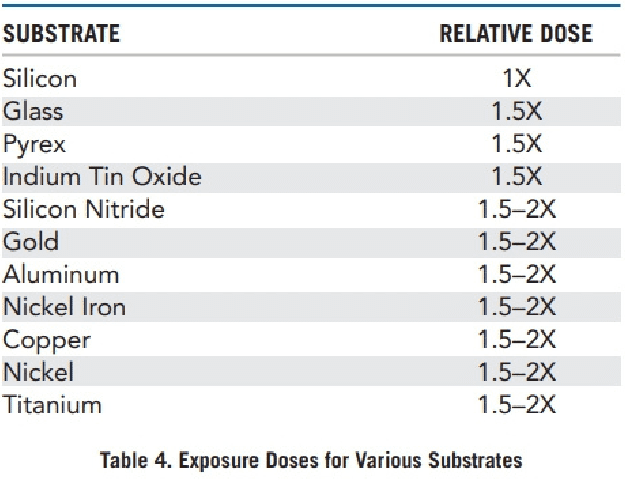

To obtain vertical sidewalls in the SU-8 3000 resist, we recommend the use of a long pass filter to eliminate UV radiation below 350 nm. With the recommended filter PL-360-LP from Omega Optical www.omegafilters.com or a 365 nm cut off filter, an increase in exposure time of approximately 40% is required to reach the optimum exposure dose.

Note:

Optimal exposure will produce a visible latent image within 5-15 seconds after being placed on the PEB hotplate and not before. An exposure matrix experiment should be performed to optimize the exposure dose.

Post Exposure Bake

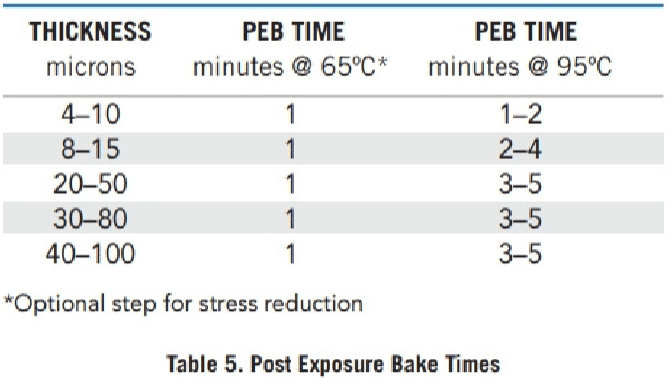

PEB should take place directly after exposure. Table 5 shows the recommended times and temperatures.

Note:

After 1 minute of PEB at 95ºC, an image of the mask should be visible in the SU-8 3000 photoresist coating. No visible latent image during or after PEB means that there was insufficient exposure, temperature or both.

Development

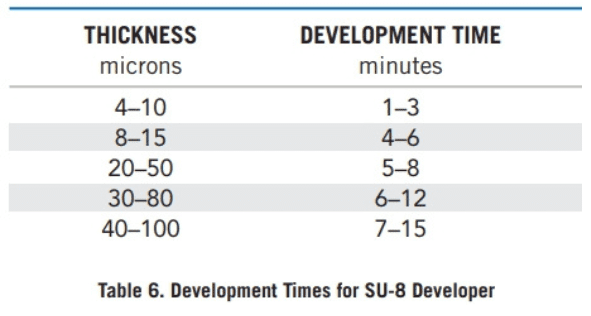

U-8 3000 resist has been designed for use in immersion, spray or spray-puddle processes with Kayaku Advanced Materials’ SU-8 developer. Other solvent based developers, such as ethyl lactate and diacetone alcohol, may also be used. Strong agitation is also recommended for high aspect ratio and/or thick film structures. The recommended develop times for immersion processes are given in Table 6. These develop times are approximate, since actual dissolution rates can vary widely as a function of agitation.

Note:

The use of an ultrasonic or megasonic bath is helpful for developing out photoresist vias or holes.