LOR & PMGI Lift-off Resists

Part of the StructSure® Line

GaAs Modulator with Al Airbridge

Source: Nortel

PMGI used as a sacrificial layer on which the airbridge was built. The PMGI layer was subsequently removed with conventional resist removal processing.

Key Features

- Won’t intermix when over-coated with imaging resists

- Single step development of bi-layer stack in TMAH, or KOH developers

- High thermal stability: Tg ~190°C

- Removes quickly and cleanly in conventional resist strippers

- Enables sub 0.25μm micron bi-layer resist imaging

- Enables high yield, very thick (>3μm) metal lift-off processing

Material Uses

- Metal lift-off processing

- Airbridge fabrication

- Release layers

Lift-Off: An enabling, additive lithographic process

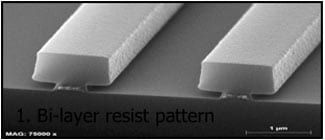

1. Bi-layer resist pattern

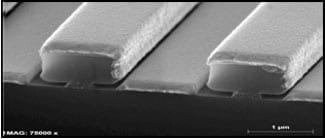

2. Metal Deposition

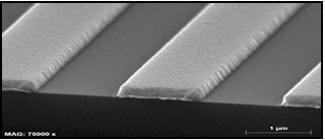

3. Clean solvent lift-off

Bi-Layer Lift-Off Process

Step 1. LOR or PMGI is coated

Step 2. The imaging resist is coated onto the LOR or PMGI layer.

Step 3. The imaging resist is exposed.

Step 4. The wafer is developed.

Step 5. Metal deposition

Step 6. Lift-off

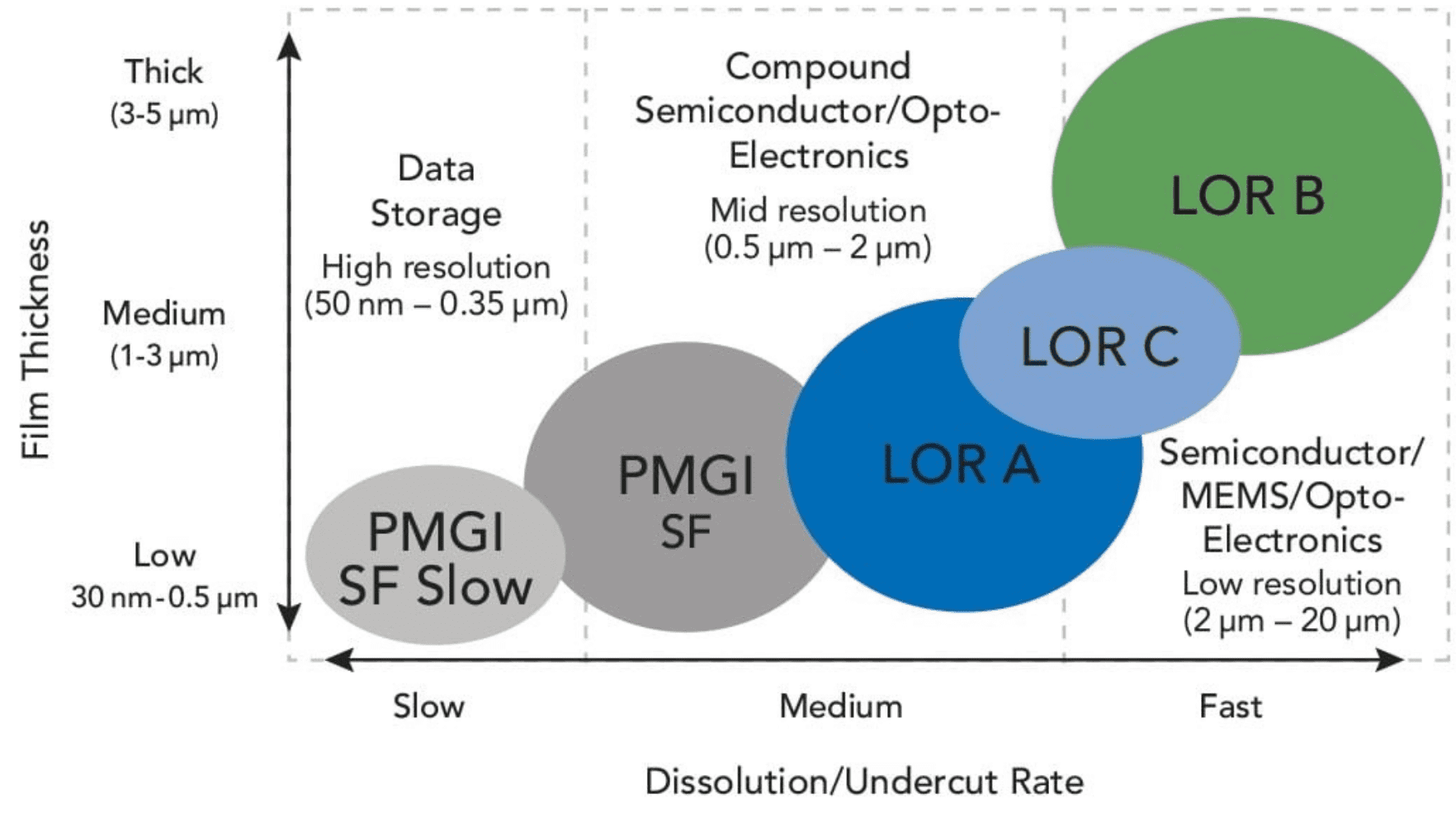

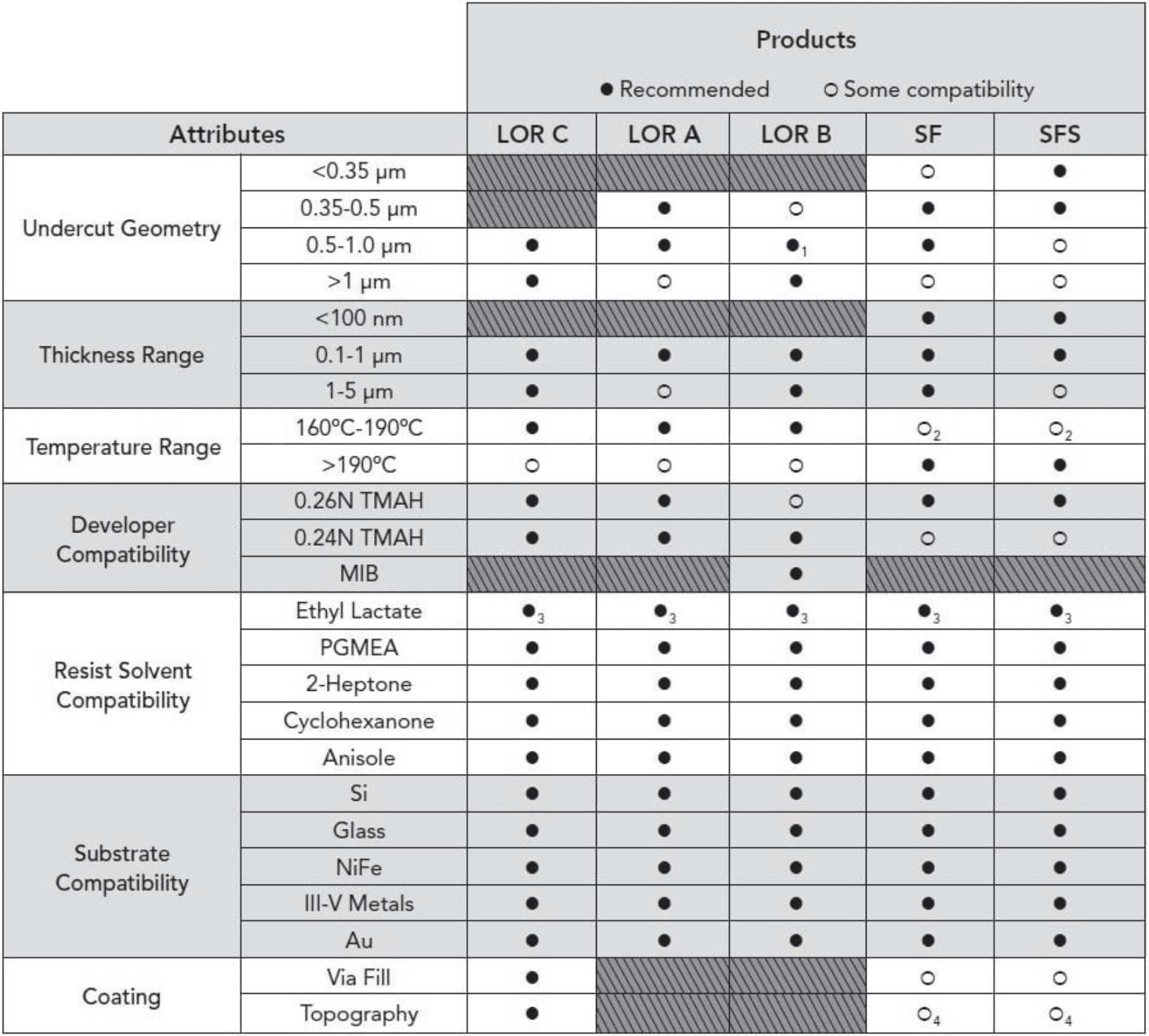

LOR/PMGI Product Selection Guide

Broad Range of Products