SU-8 TF 6000

Part of the StructSure® Line

SU-8 TF 6000 is a high-contrast, chemically amplified, negative tone epoxy-based resist that is sensitive to broadband UV radiations (i-, h- and g-Line) and is recommended wherever high resolution, photoimageable, thin, permanent structures are required. SU-8 TF 6000 is available in five standard viscosities to achieve low defect coatings with film thicknesses ranging from ~ 0.4 to 16 μm in a single coat process.

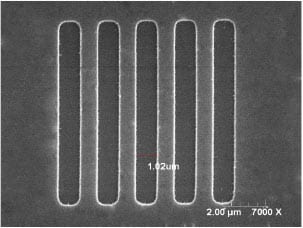

Contact aligner exposure

1 μm L/S – 0.5 μm thick SU-8 TF 6000

Source: Kayaku Advanced Materials, Inc.

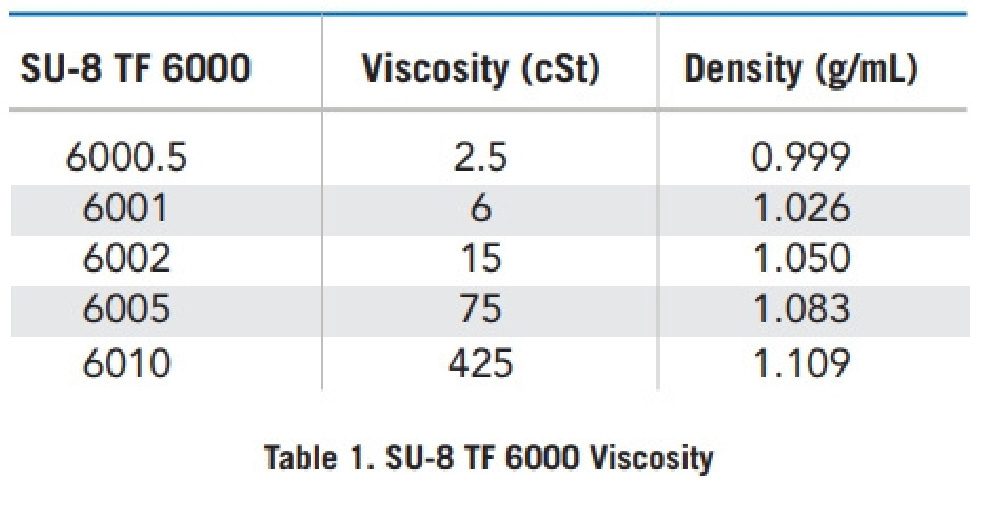

I-line stepper exposure

1 μm trenches – 0.5 μm thick SU-8 TF 6000

Source: Kayaku Advanced Materials, Inc.

Key Features

- Photoimageable thin films with high resolution i-Line patterning capability (sub-0.5 μm lines/ spaces at 0.5 μm film thickness on silicon with an i-Line stepper; and 1 μm lines/spaces at 0.5 μm film thickness on silicon with a broadband contact aligner)

- Broadband, i-Line, g-Line and h-Line sensitivity

- Low temperature cure (< 150°C)

- Highly uniform coatings and good adhesion to rigid and flexible substrates

- Outstanding thermal and chemical resistance

Material Uses

- High resolution imaging of thin permanent structures

- MEMS

- Display pixel walls and dielectric layers

Application Notes

Process Parameters

Coat

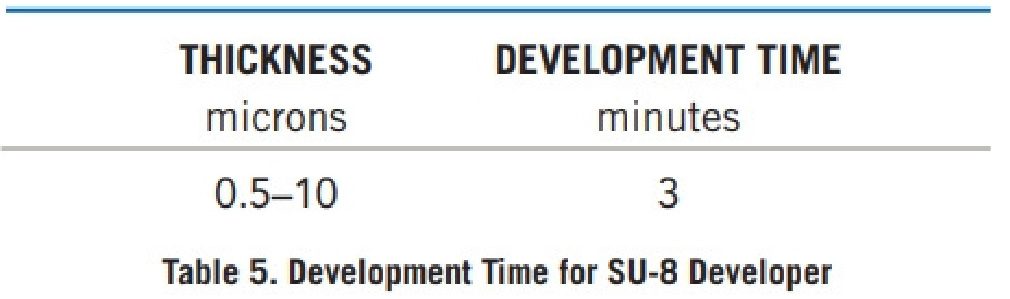

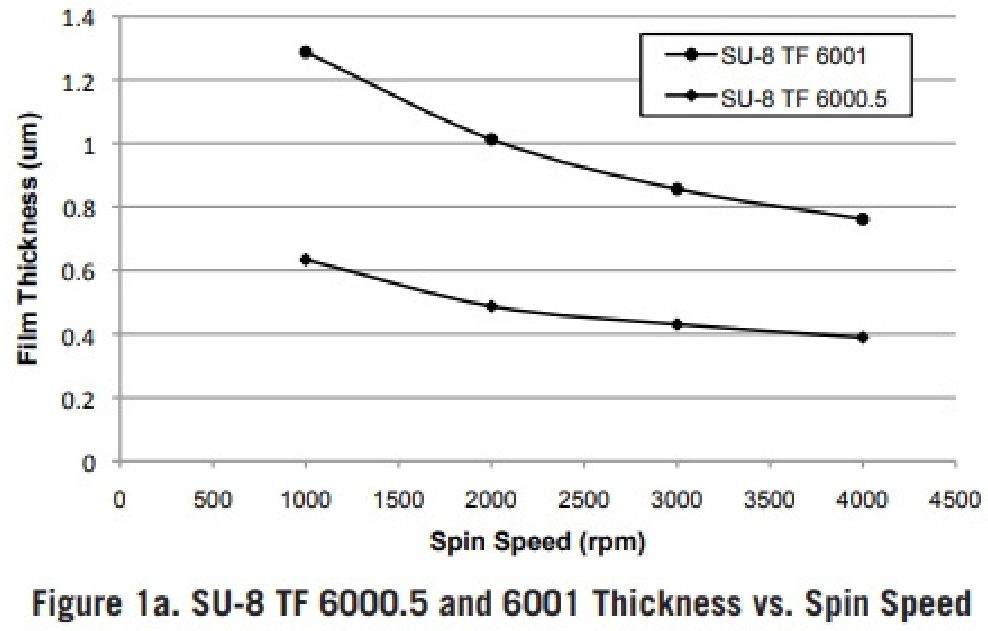

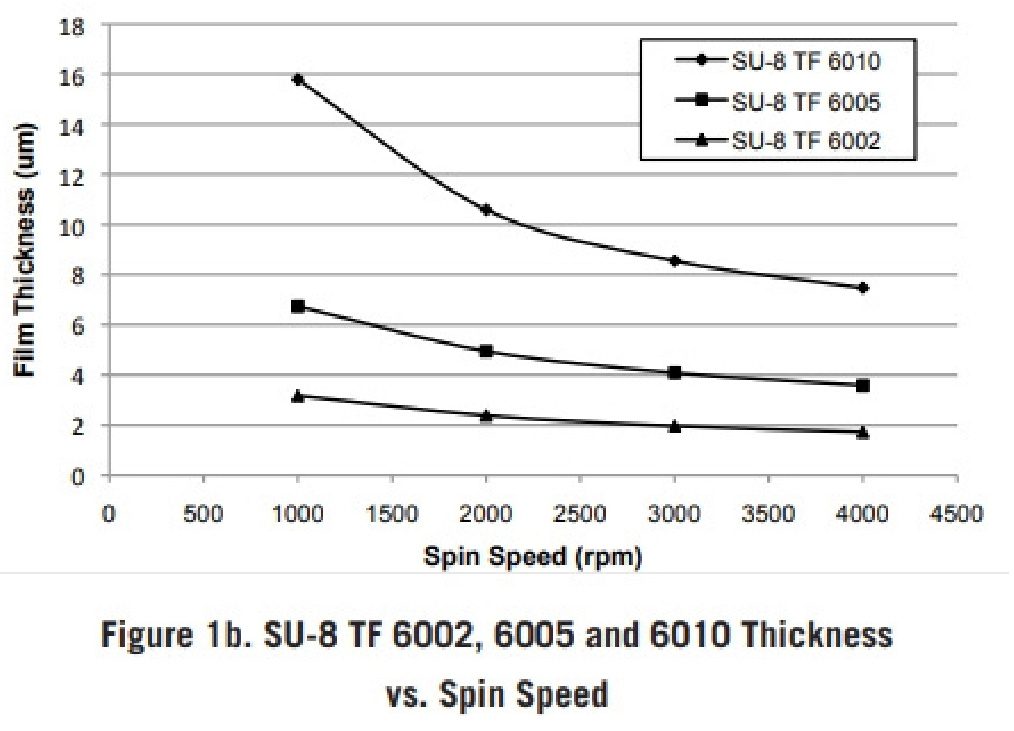

SU-8 TF 6000 resists are available in five standard viscosities, as shown in Table 1. The film thickness vs. spin speed curves are displayed in Figure 1a and 1b. The curves were generated using a Brewer Science, Model # Cee 200 coater, static dispense on 6 inch (150 mm) silicon wafers and a soft bake of 110°C (times listed in Table 2) on a level hot plate. Please note that the exact thickness obtained may be slightly offset from Figure 1 due to equipment type, coat program and environmental conditions.

Recommended Program

- Dispense 1 ml of resist for each inch (25 mm) of substrate diameter.

- Spin at 500 rpm for 5-10 seconds with acceleration of 500 rpm/second.

- Spin at 2000-3000 rpm for 30 seconds with acceleration of 500 rpm/second.

Soft Bake

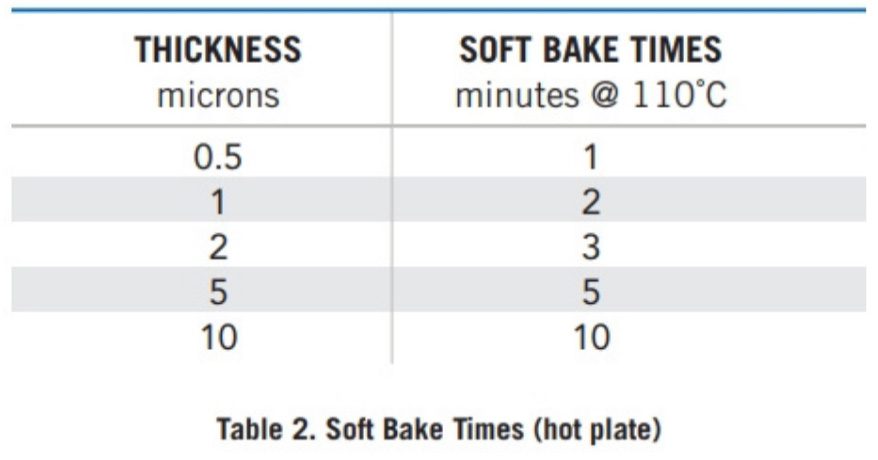

A level hot plate with good thermal control and uniformity was used for the soft bake step of the process. Convection ovens may also be used. Table 2 shows the recommended Soft Bake temperatures and times for the various SU-8 TF 6000 products at selected film thicknesses.

Exposure

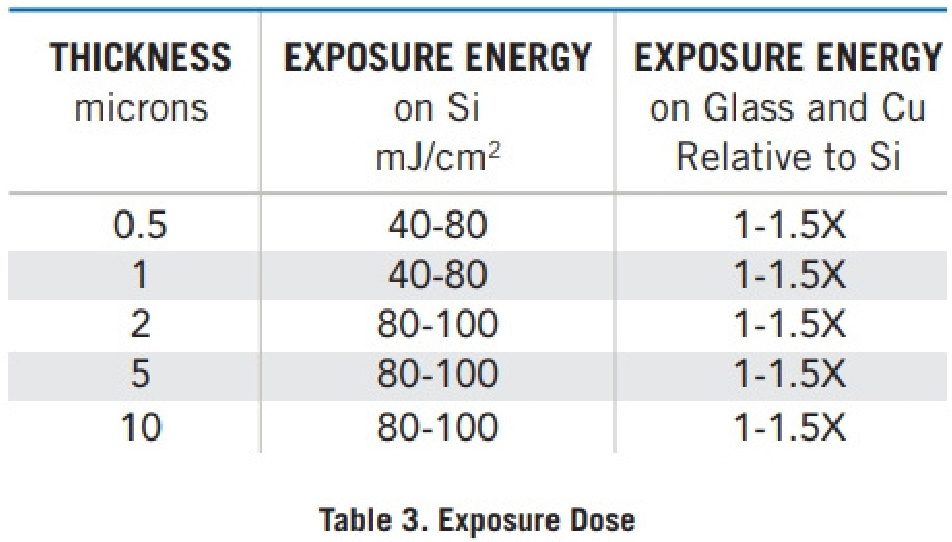

SU-8 TF 6000 resist series is compatible with i-, g- and h-Line or broadband exposure tools. Table 3 gives

the recommended baseline exposure dose to produce 10 μm lines and spaces on silicon, glass (soda lime) and copper at various resist thicknesses obtained in contact mode using an EVG 620 mask aligner with a 500 watt mercury short arc lamp and PL-360LP long pass filter (www.omegafilters. com). The exposure dose is dependent on the spectral output and measured wavelength, and should be adjusted accordingly. The use of a long pass filter to obtain vertical sidewalls in 0.5-10 μm thick films during broad band exposure is not mandatory, as T-topping is not observed for developed resist profiles in that thickness range. Without a long pass filter, the optimal exposure dose is expected to be lower than listed in Table 3.

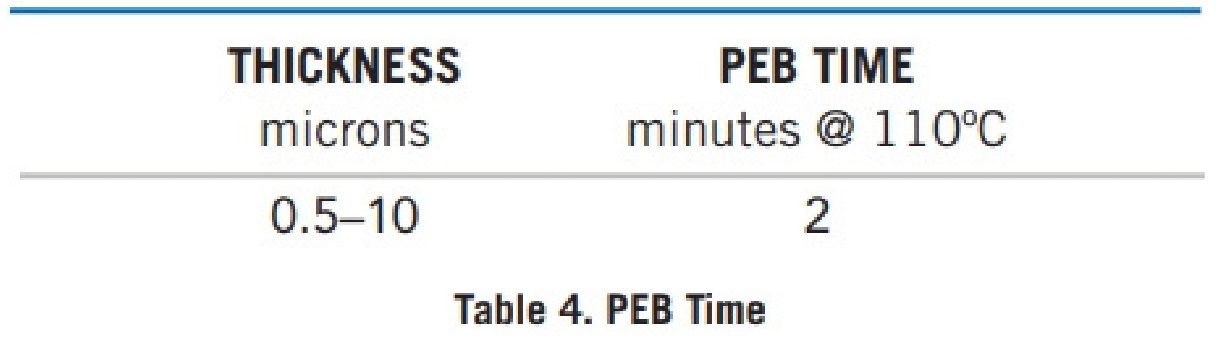

Post Exposure Bake

A post exposure bake (PEB) is required to complete the curing reaction and should take place directly after exposure.

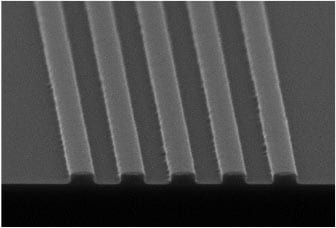

Development

SU-8 TF 6000 series resists have been optimized for development in solvent-based SU-8 Developer. They can be developed in a variety of develop modes including immersion, spray, puddle or spray/ puddle.